Earlier this month, the most-discussed topic at the day-long Federal Motor Carrier Safety Administration safety summit was the implementation of driver-assist technology throughout the trucking industry. Experts have been considering these innovations as being prevalent ways to decrease the number of truck-involved crashes.

“Nothing contributes greater to highway safety than the person behind the wheel,” said J.B. Hunt Transport senior vice president of safety, security, and driver personnel, Greer Woodruff. “But, I have seen drivers that have years of safe driving have a momentary lapse for a circumstance that unfolds, and this [technology] has saved them. They have been very thankful to have had these systems on their vehicles.”

Woodruff also noted that driver-assist systems are able to help carriers navigate the “increasing headwinds” of modern challenges, including everything from distracted driving to traffic congestion to the growing number of vehicle miles typically traveled.

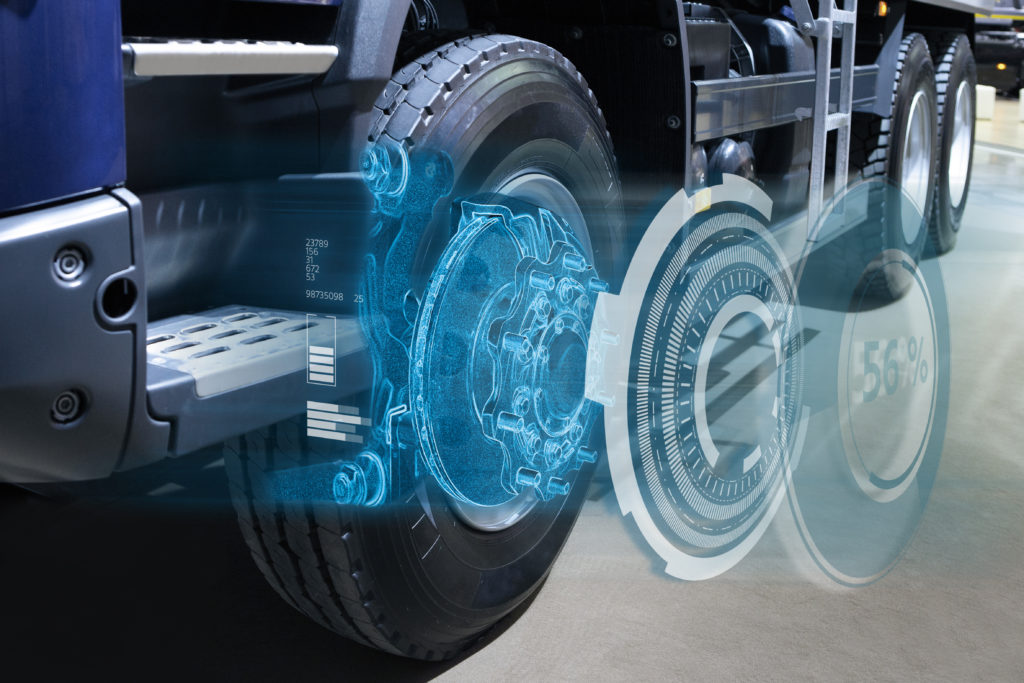

Currently, FMCSA is suggesting voluntary use of these systems by fleets and independent owner-operators. This technology includes adaptive cruise control, automatic emergency braking, blind spot warning systems, forward collision warning systems, and forward-facing camera systems.

Integration of these technologies has now reached around 45-50% of the market, according to Bendix Commercial Vehicle Systems vice president of engineering and R&D, Richard Beyer.

“These systems help the driver to reduce the stress and improve the safety,” he explained. “But it’s still based on good, solid driving practices [and] drivers staying alert and being part of the solution.”

However, two tests by AAA over the last two years have shown that partially-automated driving systems do not always work as expected, and the company has recommended that vehicle manufacturers limit the use of this technology.

AAA researchers tested the systems of five different manufacturers over a distance of 4,000 miles, and cited an issue every eight miles, on average.

“AAA has repeatedly found that active driving assistance systems do not perform consistently, especially in real-world scenarios,” said AAA’s director of automotive engineering, Greg Brannon. “Automakers need to work toward more dependable technology, including improving lane-keeping assistance.”

The majority of problems encountered by researchers involved systems meant to keep vehicles in their respective lanes; however, testing showed that many vehicles failed to detect simulated broken-down cars in their path of travel. According to the study, the test vehicles hit the out-of-commission vehicles around two-thirds of the time, traveling at an average speed of 25 miles per hour.

This recent second round of testing showed little difference from similar testing by AAA of four other vehicles in 2018. Additionally, the systems that combine braking, steering, and acceleration control continued to stop working altogether without much notice to the driver.

“When we’re talking about advanced driver-assistance systems, it really is going back to the capabilities of the driver,” said Daimler Trucks North America executive manager of advanced safety systems and autonomous driving, Ritchie Huang. “What we’re building is just supplementary to them.”

Chris Spear, President of American Trucking Associations, said the main priority for ATA is highway safety, and suggested that regulators should work toward creating an environment in which these kinds of technological innovations can explore their potential.

“I think you’ve got to stick with innovation, because it’s, quite frankly, moving 10 times faster than the government,” said Spear. “Just get out of the way. Let innovation take care of it.”

Still, AAA’s Brannon said the most recent testing on automated driving systems within personal vehicles show that systems have not been improving drastically, even though they are being implemented into mainstream models more often.

He also explained that those who first purchased the systems were typically early technology adopters, but now, more and more less tech-savvy people are operating these kinds of vehicles.

“People are really less familiar and less likely to really engage in understanding how the systems work,” Brannon said. “They just assume they do work. That could be a really dangerous assumption.”

Additionally, people easily begin to rely too heavily on the technology when frequently operating vehicles that have it in place, and Brannon said this is extremely dangerous when the systems fail in any way. AAA also explained that during real-road tests, all systems had difficulties ensuring that the vehicles remained in their lanes, and often caused the car to move too close to guardrails and other vehicles.

The issues with this current technology could, in fact, delay the adoption of entirely-autonomous vehicles, Brannon noted, because now, drivers who have operated a vehicle with the technology in place may have trouble trusting them.