We recently reported the rush for carriers to meet the August 13th deadline to purge all telecommunications equipment manufactured by five particular chinese companies. Luckily, that rush was made slightly less stressful by the Director of National Intelligence’s extension of the deadline to September 30th.

Originally, American Trucking Associations and a coalition led by the U.S. Chamber of Commerce brought anxious attention to the provision nearly hidden within the Defense Authorization Act that required federal government contractors to locate and rid their companies of prohibited Chinese-made equipment components.

These companies were believed to be U.S. intelligence and defense agency information systems hackers, and include Huawei, ZTE Corp., Hytera, Hikvision, and Dahua Technology. The requirement also included any affiliate of these companies, and industry experts said it could be immensely difficult for companies to locate these technologies within a complex modern system.

“Section 889 [of the law] seeks to prevent certain Chinese technology companies from accessing sensitive and classified information by tapping into devices they designed,” said ATA’s Government Freight Conference executive director, Bill Wanamaker. “All federal contractors, including all modes of freight carriers, have electronic systems that facilitate business processes and operate their equipment.”

The extension waiver was granted following a request given by Ellen Lord, undersecretary for acquisition and sustainment for the Department of Defense. Lord said it would be in the country’s national security’s best interest to extend the deadline.

“I am granting a temporary waiver under section 889(d)(2) until 20 September 2020 to allow the Department of Defense to continue its contracting activities that would otherwise be prohibited under section 889(a)(l)(B) and to provide additional information to the Office of the Director of National Intelligence to further assess your waiver request,” said Director of National Intelligence, John Ratcliffe, in a memo to Lord.

The U.S. Chamber of Commerce, ATA, and many other trade organizations have for months been working on a campaign to convince congressional staff to extend that compliance date by one full year.

According to an ATA Government Freight Conference analysis, freight logistics services typically use a variety of information technology systems–especially within the trucking industry.

“This corporate IT inventory is used to order freight, schedule service, provide in-transit visibility to customers, provide proof of delivery, invoice shippers, support electronic shipping documents, and pay by third-party payment systems,” said ATA in its analysis. “Motor carriers also typically use office computers, networks, internet service providers, routers, portable computers and scanners, cell phones, security systems, and video monitoring of terminals and warehouses.”

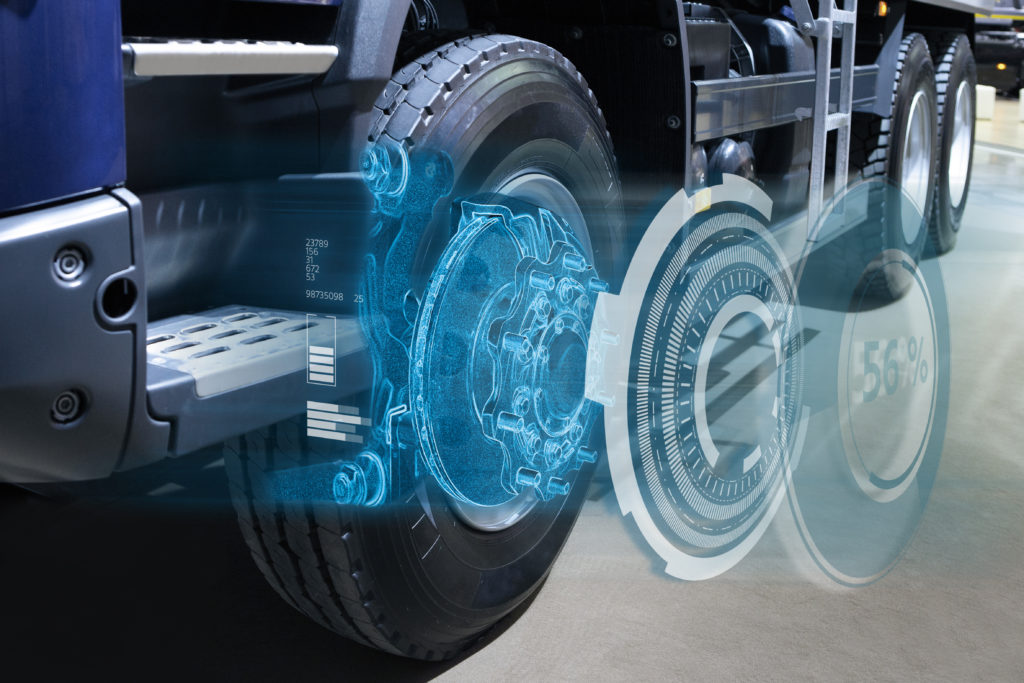

If a truck is more modern, there are more safety-focused and equipment-managing IT systems onboard, according to the analysis.

“Cameras are used for 360-degree video recording around the truck, and to replace rearview mirrors,” ATA continued. “Electronic monitoring of engines, transmissions, braking systems, tire pressure, speed, sudden braking, driver fatigue–all these things are a part of modern commercial motor vehicles. Commercial motor vehicle maintenance shops use sophisticated diagnostics to service trucks.”

Currently, the law urges federal contractors in all sectors to make their determination on compliance with this requirement by the end of September. If they fail to determine if any of the banned components are present within their systems and remove them, they risk being considered noncompliant and a potential debarment as a contractor.

“The thought that somebody six or seven levels down the supply chain could have on camera in a parking lot that invalidated one of our [contractors] being able to do business with us is cause for a bit of concern,” said Lord. “We are very, very supportive of it, but I do believe we need to extend it in terms of the time for compliance so that we don’t have unintended consequences.”

Other industry members oppose the prohibition of these components entirely, as stated in a letter cosigned by the Chamber, the Motor & Equipment Manufacturers Association, and the Alliance for Automotive Innovation, among others.

“If strictly enforced, the prohibition will effectively preclude the government from contracting with a company that has global supply chain or does business in overseas locations largely serviced by Chinese telecom networks, which includes major U.S. defense contractors,” said a document written by a Chamber coalition partner, the Aerospace Industries Association. “To implement this prohibition as currently drafted, contractors would be required to identify and remove any prohibited equipment or services that are present in their operations–including everything from the facilities they lease, to the networks they use.”